Other Parts Discussed in Thread: TPS7A05, TPS62840, TLV431

Dear all,

I have a designed a board integrating a Lora MCU (+ sensors) powered from a low powerLow noise/low voltage dropout LDO MCP1700-3302 with 170mV droupout voltage. My board is powered with a 1x D-size primary Cell with 500 mA current capability 3.6VDC with a Load when I use a new cell.

when the board is in sleep mode, the current leakage is 10uA @ 3.3VDC (=LDO Vout), and 89mA-110mA during TX mode.

I figured our the LDO is not working properly when VBAT <= VOut + DropOutVoltage, i.e. 3.45VDC , I see voltage drop and glitches on Vout leading to MCU resets due to internal brown-out circuit.

I was thinking to power the board directly from the Primary cell without using a DC-DC converter, but at high temperature the primary cell voltage can increase to 3.8VDC and this can damage or decrease Lifespan of some sensitive components mostly sensors (at 3.8VDC , the Voltage is in the Absolute Voltage Zone) , and using a zener-diode at 3.6VDC is not best solution for ultra-low-power application.

Currently I am hesitating between a LDO or a Buck-Boost converter adapted to 1x LiSOCL2 primary cell:

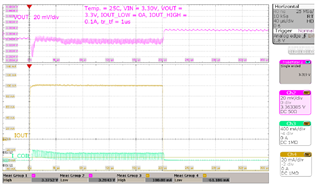

- I can use a buck-boost converter like TPS63900 but I am worried about Voltage Ripple noise +/-50mV , which can be noisy for sensors. Noise problem can be maybe solved by using ferrite Bead or electrolyte capacitors on the Vout on the voltage output .

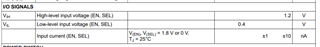

Or using a LDO TPS7A05, your specs mention it's compatible with 1x LiSOCL2 primary cell, but I am afraid to face the same problem than the MCP1700-3302 and have unexpected behavior when VBAT <= Vout + DropOutVoltage

do you have any suggestion or solution to advice ?

Many thanks,

damon

,