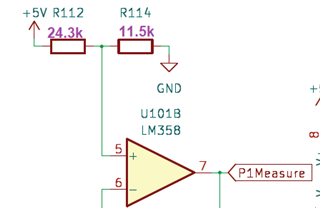

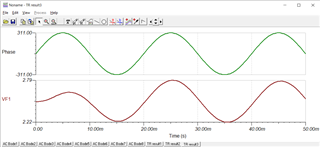

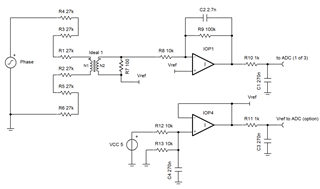

hello, I have attached herewith circuit diagram of auto phase selector. so kindly check and update as to any corrections required in this circuit??? as this is going to be used commercially and this is analog part of the circuit. microcontroller part, program I will post later for any corrections. here in this product, microcontroller will sense incoming input voltages of all three phases individually and choose best phase among three (around 220v AC) for the output load. here as I said, I am asking you to check only analog part. mcu part I will post later for any correction

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.