Other Parts Discussed in Thread: GPCCHEM

Hello,

We had completed the learning cycle using bq27520g4 and a 6000 mAh lithium polymer battery.

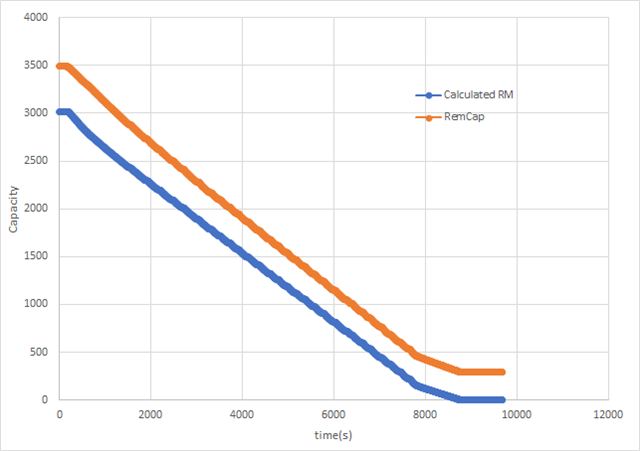

Now we want to estimate the accuracy of the guage. According to the method in this artical, we discharge the battery (the same one used in learning cycle) and record the log.

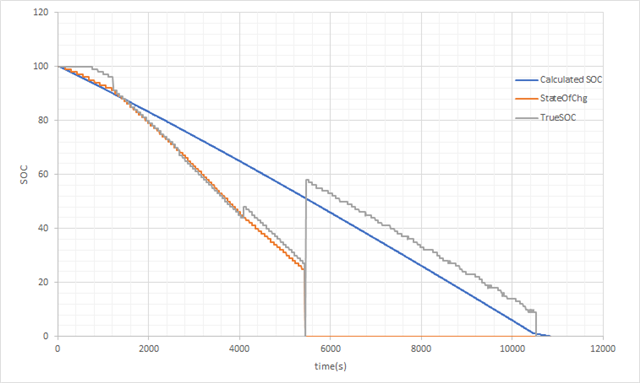

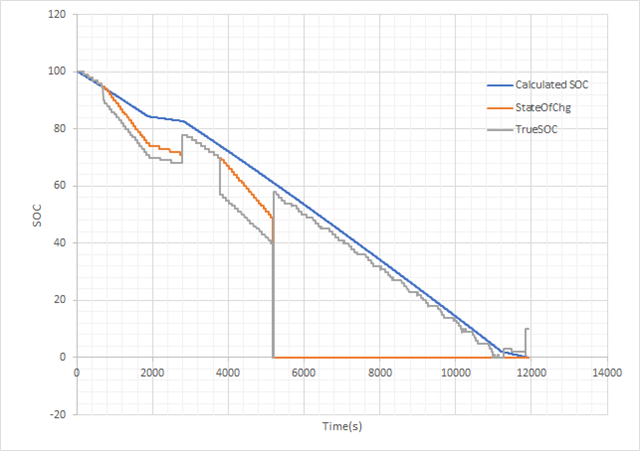

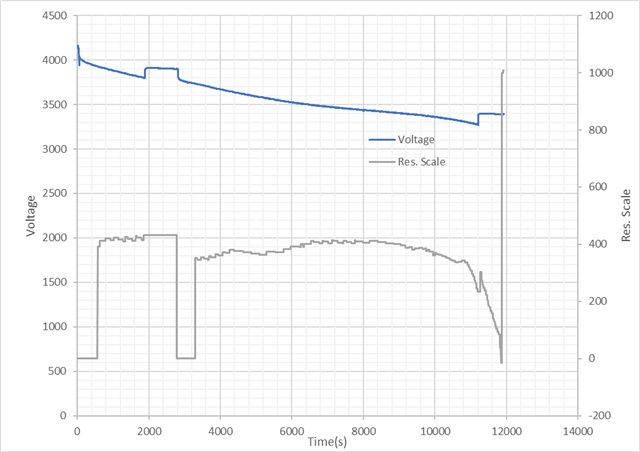

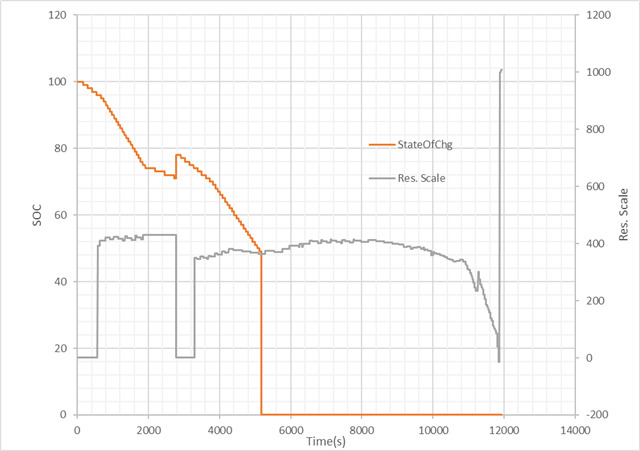

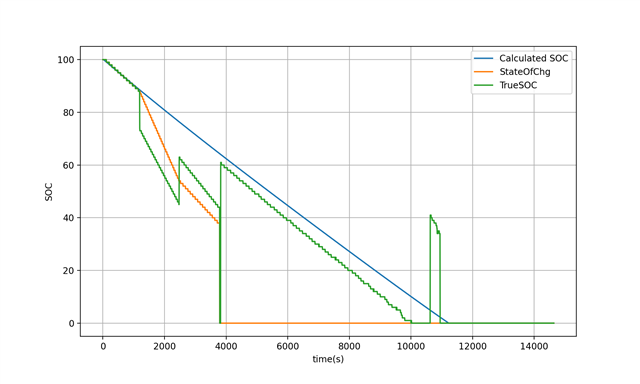

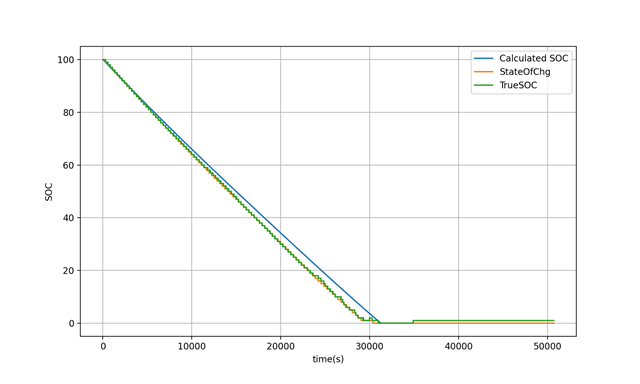

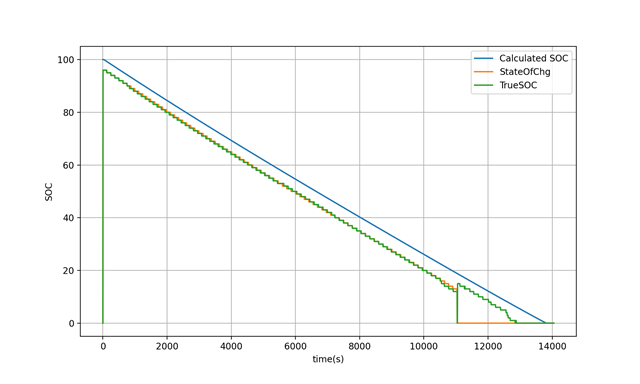

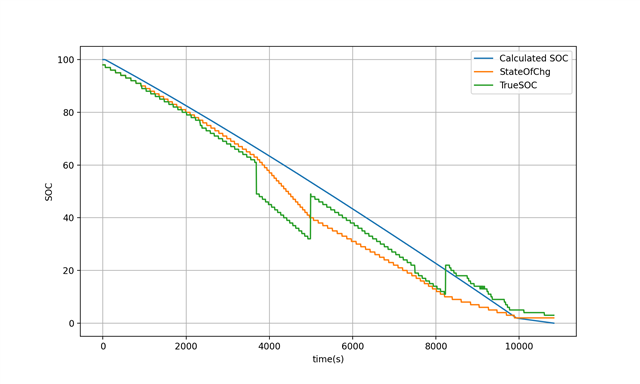

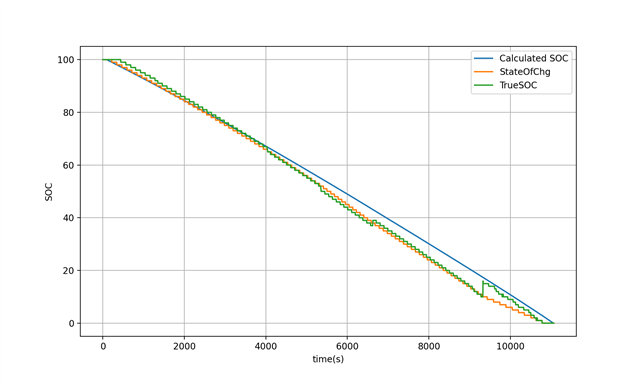

We had do the process twice, but the SOC curves were not correct.

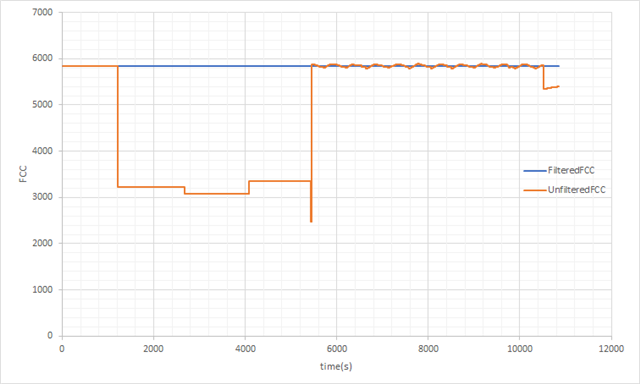

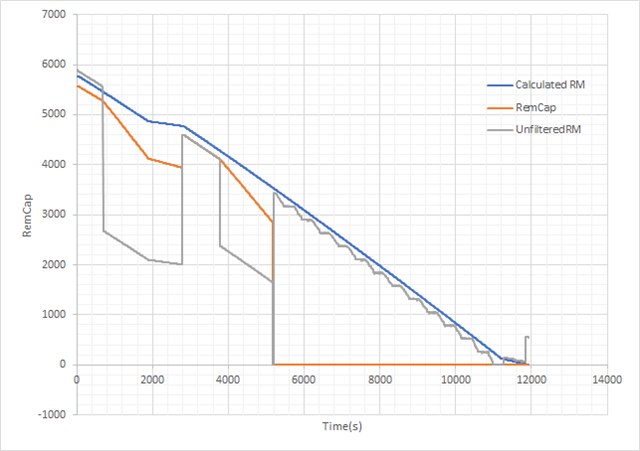

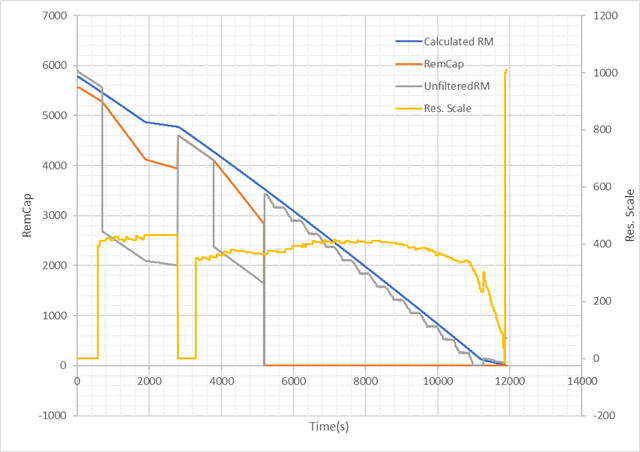

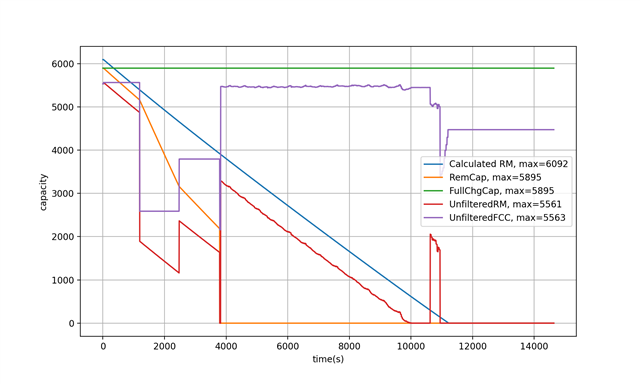

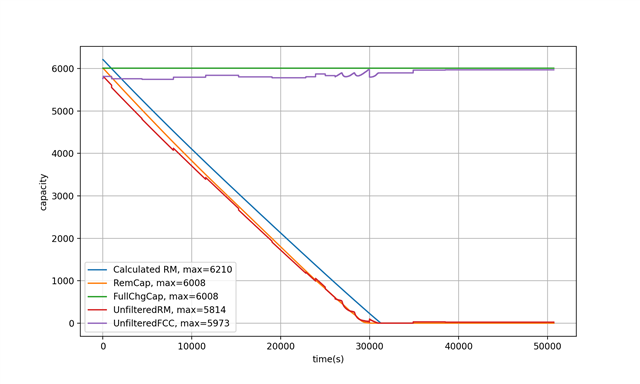

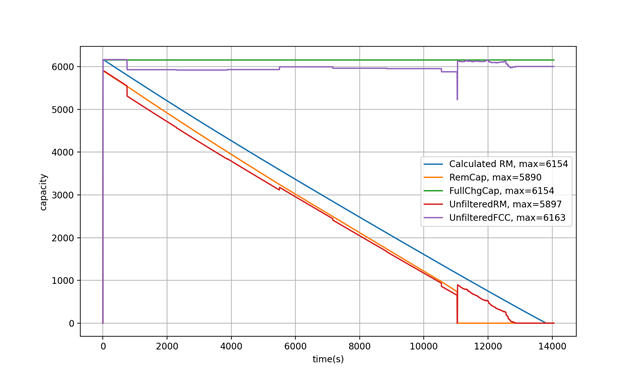

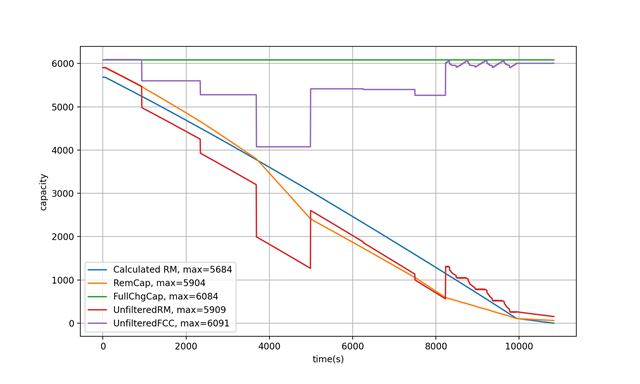

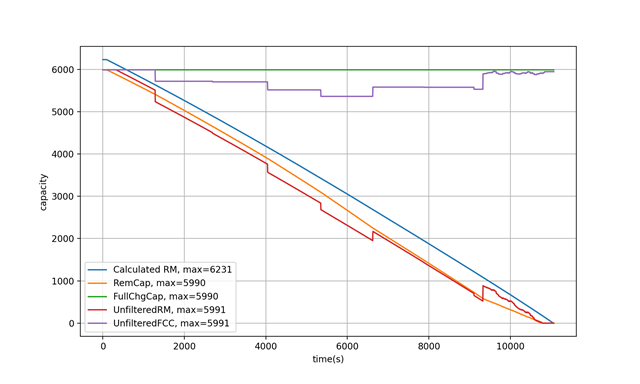

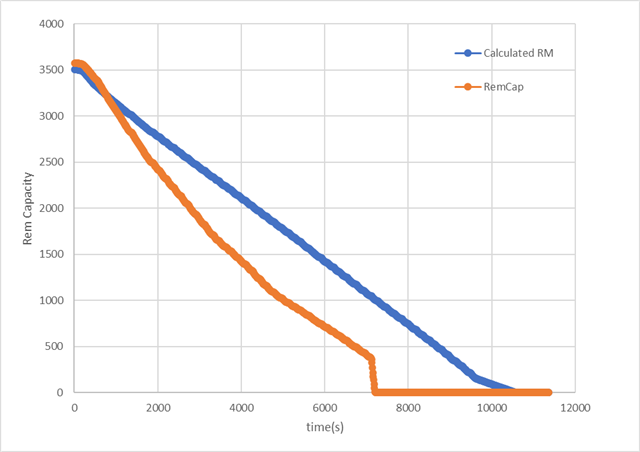

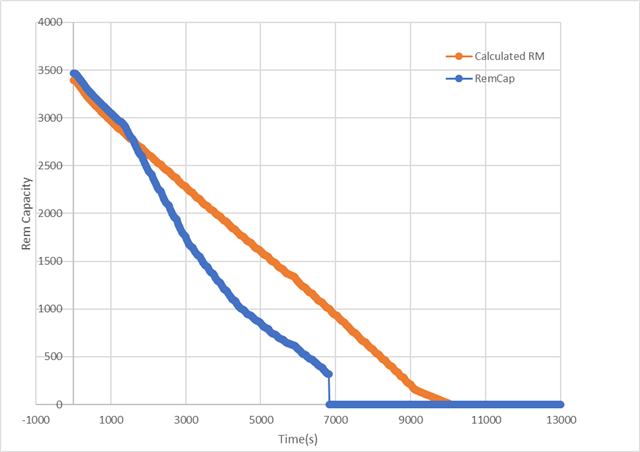

As shown in the record, the RemCap reported by gauge is not match with the Calculated RM.

In discharge_log_1, the True_SOC jump from 85% to 75%.

In discharge_log_2, the True_SOC jump from 78% to 63%.

In both log, the SOC jump from 10% to 0%.

The logs are attached.

Also, the data memory of our gauge is attached below.

Q1. What may cause the mismatch between RemCap and Calculated RM?

Q2. How to avoid the SOC jump from 10% to 0%? Is this related to Fast Resistance Scaling (our Fast Scale Start SOC is set to 10%)? What does Fast Resistance Scaling do?

Q3. According to the reference manual, when the voltage reaching the final voltage, the SOC will be force to 0%. Then what's the difference between final voltage and terminate voltage?

Q4. If the power consumption of our system is not constant (as shown in the data log), which leadings to the noise of the voltage, how should we set the final voltage or terminate voltage to make 0% SOC at proper point?

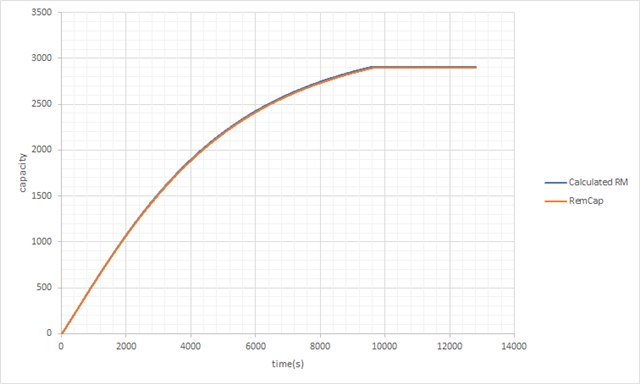

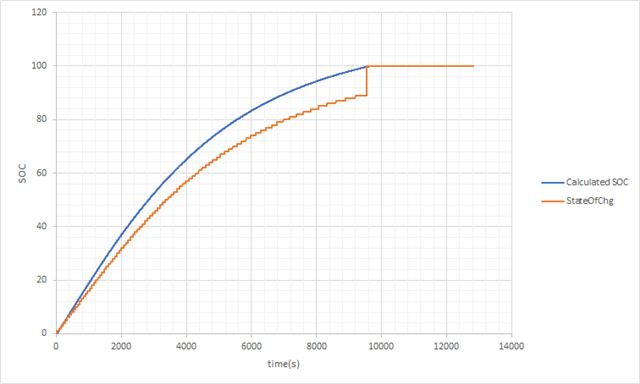

Also, we had also record the log of charging. The RemCap is perfectly accurate, but the SOC curve will jump from 92% to 100%.

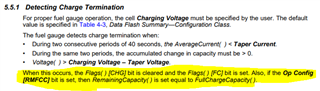

Our system has another protect IC to stop charging while current is lower than 300 mA, so the battery is not actually fully charged. We set the taper current to 310 mA. The jump of SOC from 92% to 100% as the current is lower than taper current, and FC bit is set.

Q5. We wonder if there is some setting to make the SOC curve more smooth and ending at 100% SOC without a jump.

The charge record is attached below.

Thanks for helping.

Sincerely,

Benjamin Kao