- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

Hi TI Experts,

I have the below queries regarding the VPP supply selection, configuration and application connected to the VPP pin of the SoC.

Let me know your thoughts.

Hi Board designers,

Refer below inputs for the VPP supply related queries.

The VPP is used to program the eFuse when HS-FS devices are used.

SoC devices come in two types: General Purpose (GP) & High Security (HS). All GP devices can leave the VPP domains unconnected per DM. Pre-programmed HS devices can also leave VPP supply unconnected if no additional eFuse programming is needed. If it is required to do on-board eFuse programming, VPP supply is required.

The key difference is the SOC and the VPP configuration. You need to supply the VPP supply rail during the time that eFuses are programmed,

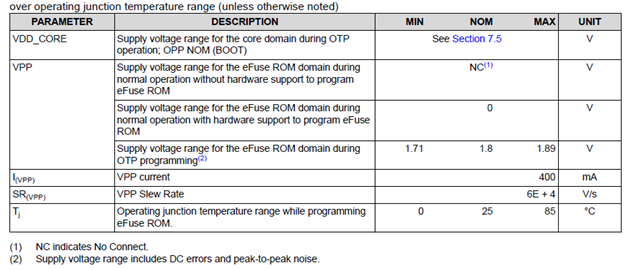

Refer section in the datasheet: 7.9.1 Recommended Operating Conditions for OTP eFuse Programming.

An LDO low-dropout with fast transient response, quick output discharge and capability to enable to output is recommended. PMIC with LDO output meeting the datasheet ROC (Recommended operating conditions) can be used.

A fixed output LDO is recommended. When an adjustable LDO is used, consider adding an external zener based over voltage protection at the LDO output and provide a provision to isolate the LDO output connected to the processor VPP supply pin. Test the LDO output performance before connecting the LDO output to the VPP supply pin.

Given the high load current transient requirement during eFuse programming, load switch or FET switch may not be a recommended approach, It is recommend using a 400mA LDO. A load switch is likely to have too much voltage drop that can't be compensated like when using an LDO.

The 1.8V source for VPP should have an internal active discharge function that gets turned on when the source is disabled to ensure VPP is held to 0V during normal operation.

The VPP voltage is not recommended to be supplied when the eFuse write is not being done.

VPP should only be powered while security key programming is done. It should be powered off during all other times, including normal active use of the SoC. This is the reason for VPP supply not being shared with other peripherals, which are required to be powered at all times.

An OTP (One Time Programmable) Keywriter (software tool) is used to program the eFuse. The keywriter controls the On-Board LDO that is used to generate the VPP supply voltage via a GPIO output.

An alternative way to source the VPP is to use an external supply. The required caps and termination/Discharge resistor are recommended to be placed near to the SoC VPP pin.

A custom VPP Programming board using an LDO similar to the On-Board LDO used in the EVM can be designed and the LDO can be enabled via the GPIO output.

https://www.ti.com/lit/zip/sprr275

(refer to file VPPPROGRAMMINGBOARD_3J0002_REV1_0A.PDF).

Recommended LDO

https://www.ti.com/product/TLV755P/part-details/TLV75518PDQNR

In case an external power supply is used, The GPIO output can be used to control or time the external power supply output.

Programming sequence for OTP eFuses:

• Power on the board per the power-up sequencing. No voltage should be applied on the VPP terminal during power up and normal operation.

• Load the OTP write software required to program the eFuse (contact your local TI representative for the OTP software package).

• Apply the voltage on the VPP terminal (according to the specification in Section 7.9.1 of the datasheet).

• Run the software that programs the OTP registers.

• After validating the content of the OTP registers, remove the voltage from the VPP terminal.

Reference: Section 7.9.3 Programming Sequence of datasheet

Do not connect the SOC VPP pin. Leave it open. Alternatively, you could terminate to ground externally.

Used as GP device and could be used as HS-FS device in the future

Provide a provision to add a discharge resistor 1K. The pull-down value needs to be to select such that it doesn't allow any leakage path through the LDO to source a potential greater than 0V when disabled.

Provide provision for low loop inductance bulk (2.2 uF) + decoupling (0.1 uF) capacitor(s) located near the VPP pin.

Populate the discharge resistor and DNI the capacitors.

Used as only GP device (no HS-FS)

The VPP pin can be left open or a 1K resistor can be added with a TP for Just in case usage.

The VPP power rail is required to be powered during the programming of the eFuse array. It should not be powered during normal operation. An always VPP supply is not allowed or recommended.

Device reliability was never evaluated for an operating condition where the VPP power rail was connected to an always on power source. Take care to connect the LDO to a GPIO such that it defaults to the off state and the TI keywriter software will apply power to VPP when appropriate.

The VPP power rail requires load current transients to blow the metal fuses in the eFuse array, so it would be almost impossible to maintain the ROC voltage range on the VPP pin without providing a very low loop inductance bulk decoupling capacitor(s) located near the VPP pin. It is important the customer validate VPP never drops below the min ROC value during programming to ensure the fuses are burned properly. The fuses may appear to be blown but could be marginal if the VPP is allowed to drop below the min ROC value even for the shortest period of time during programming. VPP supply has to be characterized to ensure they are within the ROC during programming.

Refer the below section of the device specific datasheet.

7.9 VPP Specifications for One-Time Programmable (OTP) eFuses

14. Does the above guidelines apply for AM64x, AM62A7, AM62A3, AM62P and AM62Px devices?

It is Ok to follow the described guidelines/recommendations for the above-mentioned devices

15. On the SK TLV75518PDQNR is used. Is there an LDO recommendation for automotive applications?

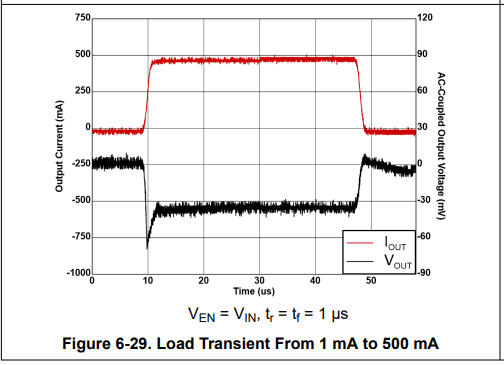

Load Transient characteristics is required to be comparable to the power supply used in the SK (TLV75518PDQNR).

or other automotive LDOs another recommendation would be TPS7A21-Q1 which showcases good transient response.

Currently, we are sampling the 1.8V output option of this LDO, P7A2118PQWDRBRQ1. The full release MPN of this LDO will be TPS7A2118PQWDRBRQ1.

Note on LDO selection

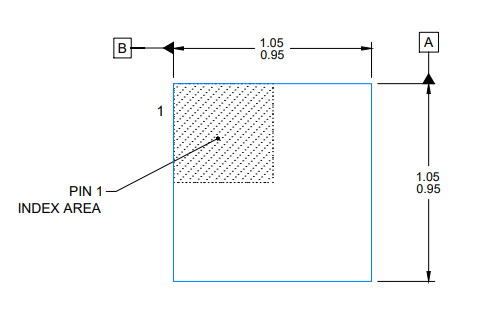

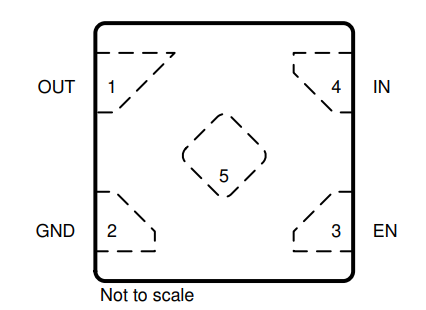

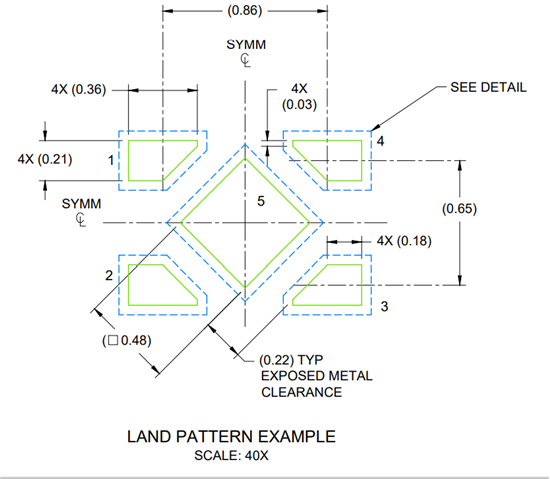

TLV75518PDQNR is device in DQN Package, 4-Pin X2SON

Refer below device outline

There is a likely chance of assembly error due to the LOD outline, pins orientation

and the land pattern (pads and pitch)

Note: An alternate package could be selected based on the space availability can be chosen. Alternative be sure to include the LDO assembly caution note during board assembly.

eFuse programming supply use case summary

The VPP pin is only allowed to be powered during programming. So the system design must provide a way for software to only apply power during programming of the eFuse array. We do not recommend a load switch or a DC/DC source due to the high transient currents required to blow the fuses. We recommend the VPP pin be sourced directly from a dedicated LDO that has good transient response. Even then the system designer needs to validate their specific solution doesn’t allow the VPP pin on the processor to ever drop (not even for a very short period of time) below the minimum ROC voltage while programming the eFuse array. They may need to minimize trace inductance and/or increase decoupling capacitors as necessary to ensure this operating condition. This is the reason it is not possible to power VPP from a shared power source.

Additional References

Regards,

Sreenivasa

Hi Board designers,

Refer below additional inputs for the VPP supply related queries.

16. We need to supply all the power of SOC while we're writing, right? Or should we just supply VPP power?

17. Is there a concern if there is a abrupt VPP supply failure or SOC supply failure while the Keys are being written to the eFuse from the SOC hardware point of view.

It is highly recommended to have stable power source when running key programming.” Any abrupt power failure on VPP or SoC during key programming would lead to un-expected consequences, i.e. unrecoverable.

18. If power supply interruption interrupt during writing, is it possible to start writing again from the beginning?

- In case of power failure of VPP/SoC during the function Sciclient_service() execution, the consequence is unexpected, and most likely, it is impossible to re-run key programming again.

19. Is it possible to control the GPIO of the SOC while writing?

HI Board designers,

Refer below additional queries answered

Using external supply should not be a concern. it is important to follow the power sequencing requirements. The SOC supplies should have ramped up and be stable before applying the VPP. It is recommended to switch off the VPP before switching off the SOC supply. Since an external voltage source is used, a 2.2 uF + 0.1 uF cap is recommended near to the SOC VPP pin due to the load current transient requirements.

Also note the below inputs i received from the device expert:

All customers must validate their VPP source impedance and confirm it never allows the AM62x VPP pin to drop below the min value defined in the ROC table for any period of time during eFuse programming. The VPP load current transient is very high short duration pulses so this validation is very important to ensure the fuses in the eFuse array are properly burned.

The recommendation is to use an SOC IO to time since this ensure the power sequence in additional to the ON time. It should be OK to have the VPP supply ON for few seconds before the key writer routine is executed and switch off a few seconds after the key writing routine is executed. The key is the VPP supply should be within the ROC all the time and also the supply sequencing is followed.

Note on Keeping VPP on for longer than required time:

The biggest concern with apply a potential to VPP when not programming the eFuse array is an increased probability that the eFuse array could accidently be programmed if something unexpected happens and rouge code writes to the eFuse array. There should not be any problem if they ensure this never happens.

①If we interrupt writing in the middle, is it possible to start writing again from the beginning?

→No. It is impossible.

→In case of power failure of VPP/SoC during the function Sciclient_service() execution, the consequence is unexpected, and most likely, it is impossible to re-run key programming again.

②What kind of problems can be expected if there is a power loss in the middle of writing?

→ In case of power failure of VPP/SoC during the function Sciclient_service() execution, the consequence is unexpected

③How can we check if the writing was successful? Is there a register to store the write results?

→***I should ask another thread.***

④We need to supply all the power of SOC while we're writing, right? Or should we just supply VPP power?

→SOC is expected to be supplied with all supplies. the supplies are expected to be ramped and stable.

⑤Is it possible to control the GPIO of the AM62A while writing?

→Yes. the LDO EN is controlled by the GPIO.

→Yes. R5 SRC code is owned and re-buildable by user, and it is possible to configure peripheral, i.e. GPIO in R5 code.

Regards,

Sreenivasa

HI Board designers,

Refer below additional queries answered

For functional safety, is monitoring eFuse supply required.

I suspect NO as the only time VPP needs to be applied is during OTP programming, so a security update related

Step like firmware anti-rollback or key revocation – and I would not expect these tasks to be triggered at the same time

the application is performing a safety function. We should confirm that w. the customer but likely they can mark as not

safety related in the FMEDA.

Are we recommending that the customer switches VPP on only when programming OTP or are we just telling them to connect it always on?

Only when programming the eFuse array.

Monitoring of VPP supply is not required.

There is an underlying assumption that should go into the Safety Manual if it’s not there – and that is basically that

Any operations involving OTP programming are not carried out when the safety task has started, as we consider

OTP programming as not safety related.

Regards,

Sreenivasa

HI Board designers,

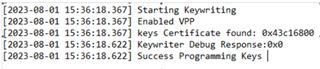

Refer below an example of the Key writer timing for a specific use case (could be used as an indication of the timing):

The keywriting take about 250-300 ms. The keywriter size is 296KB with the Key blob and the above doesn`t include time needed to transfer the keywriter from host. Keywriter loading time from host to target depends on the boot media eg UART will be slow (115.2kbps) while USB DFU will be fast (400 MBps)

Regards,

Sreenivasa

HI Board designers,

Additional inputs on the VPP supply slew rate

Refer device specific data sheet section related to VPP

7.9 VPP Specifications for One-Time Programmable (OTP) eFuses

This section specifies the operating conditions required for programming the OTP eFuses.

7.9.1 Recommended Operating Conditions for OTP eFuse Programming

Regards,

Sreenivasa

Hi All,

Inputs regarding Key Write

https://www.ti.com/lit/an/spracz6/spracz6.pdf

Processors_Security_Overview_v1.PDF

Regards,

Sreenivasa

HI Board designers,

Inputs regarding Key Write changes when an IO that is not similar to the IO used on the EVM or SK

We enable the voltage via a GPIO pin from main. We can drive the GPIO pin in Linux code via gpiochip command and confirm that VPP pin is at 1.8V.

When we use the GPIO code shown above by Hema, we CANNOT drive the GPIO pin high.

We understand that the eval board schematics uses a GPIO via a port expander to enable VPP. Our use case is much simpler, we just need to configure a pin to be an output and drive it high.

For any board revision, please follow the below procedure for controlling the VPP via the GPIO.

- The relevant GPIO pin is configured in the Sysconfig. This is required for auto generation of the pinmuxing code.

- The relevant GPIO is used in the `keywriter_setVpp` function.

FYI, please refer to the following response where a customer successfully controlled VPP via GPIO

Regards,

Sreenivasa

HI Board designers,

Here are some additional information on the use of LDOs FET switch

I compared the behavior with the TLV75518 and TPS7A21-Q1 LDOs that we have been recommending.

The voltage seems to be within the ROC and the slew rate matches the data sheet requirement.

They need to characterize their system by measuring the voltage on the processor VPP pin during programming and make sure it never drops below the ROC min limit for even the shortest period of time. There are too many variables in the path of VPP to be sure without characterizing their implementation.

Regards,

Sreenivasa