Tool/software:

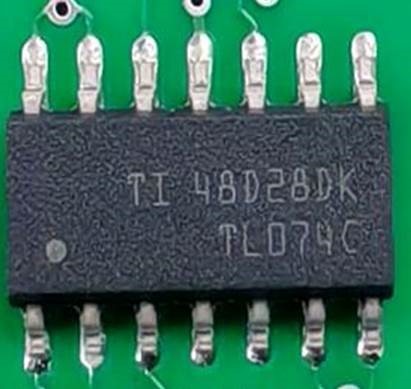

Our team found failure more than 50% at ICT. After checked the differences between passed and failed board and found difference at this part number TL074CDR.

Kindly help to check with supplier. We observed different marking on the component body between the pass and fail components. We need TI to please advise on the difference/ changes between these 2 IC’s. Please treat this as urgent case as we are having high failures and possible shipment delinquency if not resolved at the soonest.

|

Body marking on passed board |

|

Body marking on failed board |

Incoming history:

|

Item |

Manufacturing Part # |

Supplier |

Packing Size |

Receipt Number |

Order Number |

Receiving Date |

Date Code |

|

AGIH-VR-1826-1622 |

TL074CDR |

SP7U1436X |

1250 |

WR6276888 |

70GL17208 |

10/9/2024 10:14 |

2433 |

|

AGIH-VR-1826-1622 |

TL074CDR |

SP7U1436X |

1250 |

WR6276888 |

70GL17208 |

10/9/2024 10:14 |

2433 |